Lean Six Sigma is a powerful methodology for streamlining processes and reducing waste. By adopting its principles, organizations can dramatically enhance efficiency across various departments. Essential to this approach is the focus on reducing defects and variations in processes, leading to boosted productivity and enhanced customer satisfaction. , Additionally, Lean Six Sigma emphasizes continuous improvement through data-driven decision evaluation and the active involvement of employees at all levels.

Six Sigma Demystified: A Journey Towards Process Excellence

Embark on a transformative quest through the world of process improvement with Six Sigma. This powerful methodology Lean Six Sigma methodology empowers organizations to minimize defects and achieve operational excellence. By implementing its rigorous framework, businesses can optimize critical processes, leading to increased customer satisfaction, reduced costs, and improved output. Six Sigma's essential principles involve data-driven decision making, process mapping, and continuous improvement initiatives. Through its structured phases—DMAIC—Define, Measure, Analyze, Improve, and Control—organizations can systematically identify root causes, implement corrective actions, and monitor progress. By mastering Six Sigma, businesses can unlock unprecedented levels of achievement

Embracing Lean Management for Continuous Improvement

In today's dynamic and competitive landscape, organizations are constantly strivingto improve their efficiency. Lean management has emerged as a powerful framework that supports businesses to achieve this goal through continuous optimization. By eliminating waste and optimizing processes, lean principles help organizations {deliverbenefits to their customers more effectively while enhancing profitability. A key element of lean management is its concentration on employee engagement, as they are often the best source of solutions for improvement. By cultivating a culture of continuous learning and growth, organizations can tap into the full potential of their workforce and achieve sustainable success.

Implementing Lean Principles in Your Organization

Embracing lean principles can significantly enhance your organization's overall performance. By focusing on reducing waste and optimizing processes, you can boost efficiency and provide greater value to your customers. A key aspect of lean implementation is encouraging continuous improvement through teamwork. By involving employees at all levels in the process, you can build a culture of creativity. A well-structured lean journey typically consists identifying areas for development, developing clear goals and metrics, launching changes in stages, and continuously evaluating progress. Remember that achieving results with lean requires a engaged effort from everyone within the organization.

Introducing DMAIC in Six Sigma: Your Guide to Solving Problems

The DMAIC roadmap is a structured and data-driven approach used within the robust Six Sigma methodology to successfully tackle complex problems. Each letter in DMAIC stands for a distinct phase: Define, Measure, Analyze, Improve, and Control. This cyclical process allows organizations to systematically identify root causes of issues, develop solutions, and ensure long-term effectiveness. By following the DMAIC framework, businesses can enhance operational efficiency, reduce defects, and finally achieve significant improvements in their core competencies.

The DMAIC methodology is a powerful resource for any organization seeking to streamline its processes and drive continuous improvement. Its defined framework provides a solid foundation for problem-solving, while its data-driven approach ensures that solutions are evidence-based.

Lean Thinking's Impact on Today's Companies

In today's rapidly evolving market dynamics, companies are constantly seeking ways to optimize their processes. Lean thinking, a powerful methodology that focuses on eliminating waste and maximizing value for the customer, has emerged as a key strategy for achieving this goal. By identifying and removing non-value-added activities, businesses can streamline operations, reduce costs, and improve overall productivity. Lean thinking also promotes continuous improvement, encouraging employees to actively participate in identifying areas for optimization and implementing innovative solutions. The result is a more adaptable organization that is well-positioned to thrive in the face of industry disruptions

Angus T. Jones Then & Now!

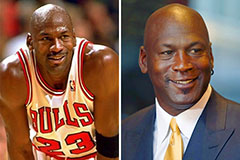

Angus T. Jones Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Andrew McCarthy Then & Now!

Andrew McCarthy Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!